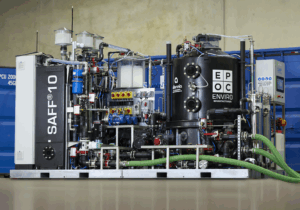

EPOC Enviro launch lean and nimble SAFF®10 PFAS remediation technology

Australian company EPOC Enviro today launched the SAFF®10, a compact new PFAS remediation technology developed in response to industry demand and engineered for sustainability.

The SAFF®10 joins EPOC’s existing suite of SAFF® PFAS remediation technologies, and is ideal for sites with limited space, accessibility issues, and low or intermittent water flows.

Surface Active Foam Fractionation (SAFF®) represents a sustainable approach to PFAS remediation, where a combination of sustainable engineering and biomimicry using air bubbles is used to rapidly ‘foam out’ more than 99 per cent of target PFAS molecules, enabling treated water to be safely returned to the environment.

“PFAS pollution doesn’t always happen on a grand scale, and neither should the solution. As the smallest system in our SAFF family, the SAFF®10 is built for places where other systems simply won’t fit,” said EPOC Enviro Managing Director Peter Murphy.

“With a trim footprint of just 2.3m x 4.6m, the SAFF®10 is an ‘unboxed’ versatile solution that can be housed in an existing room; positioned into a 20ft container; or mounted on a trailer for sites requiring a mobile solution,” he said.

“This versatile alternative runs on EPOC Enviro’s award-winning SAFF® process, so remediators know they’re getting a proven and effective solution that removes target PFAS contaminants without the waste: same clean water outcome, smaller environmental footprint.”

The SAFF®10 can comfortably process 75,000 litres a day, even in complex water chemistries and includes both primary and secondary foam fractionation for superior PFAS capture.

It’s an ideal technology for remediating target PFAS contaminants in any number of applications including landfill leachates, groundwater, trade waste, mobile and fixed foam deluge system decontamination, spill incident waters, and more.

Key features:

- Throughput up to 10m³/hr

- Modular, skid-based system

- Includes dosing capability for enhanced uptake of short chain PFAS contaminants

- Robust technology capable of managing an array of water types and PFAS concentrations

- Mobile, lightweight, forkliftable

EPOC Enviro first conceived of Surface Active Foam Fractionation as a method for PFAS removal in 2015. The patented technology has now successfully treated nearly 1.5 billion litres of PFAS impacted waters across three continents, with operational systems at both Oakey (QLD) and Shoalhaven (NSW) within Australia, and several more on the drawing board.