Fuel and fertiliser for the future: regional hydrogen and ammonia power Aussie farming

Hiringa Energy, Sundown Pastoral Company and the NSW Government have announced Financial Close has been reached on their Good Earth Green Hydrogen and Ammonia (GEGHA) project.

GEGHA has satisfied all development milestones, with construction scheduled to begin in October this year. This achievement highlights the sustained opportunity for Australia’s green hydrogen industry, proving right-sized, demand-led projects can succeed.

The GEGHA project is an integrated solar energy to low-carbon hydrogen and ammonia operation. Once complete the plant will be located adjacent to Sundown’s Joint Venture Wathagar cotton ginning facility, near Moree NSW.

GEGHA will produce up to 4,500 tonnes of low-carbon ammonia annually, displacing high-carbon fossil fuel-based nitrogen fertilisers and removing up to 17,000 tonnes of CO₂-equivalent emissions each year – the same as taking 6,500 passenger cars off the road or planting half a million trees.

GEGHA fertiliser will be consumed by Sundown to support production of its positive net-zero, traceable Good Earth Cotton, with excess supply also available for other regional growers.

In addition to ammonia production, the facility will supply ~224 tonnes of green hydrogen per annum for direct use. Green hydrogen is set to be consumed as part of Hiringa’s heavy-vehicle refuelling network, as well as on-farm to displace diesel in irrigation pumping, further decarbonising the agricultural supply chain from paddock-to-port.

“Getting the green light for green fertiliser production isn’t just about producing low-carbon ammonia,” says Hiringa co-founder and CEO Andrew Clennett.

“It’s a model for overcoming the obstacles that have held back the establishment of these new green industries. By strategically partnering with Sundown Pastoral Co, we’re anchoring demand with supply to meet the immediate needs of the agricultural sector.”

Transforming supply chains

GEGHA will offer East Coast Australia’s first green fertiliser supply, delivering regional producers with competitive, stable pricing for their fuels and feedstocks.

The plant will use renewable energy to generate hydrogen via electrolysis, which will then be used to make ammonia fertiliser with negligible CO₂ emissions.

Conversely, ammonia used in traditional fertilisers is made with natural gas or coal, resulting in high carbon emissions. The current fertiliser supply chain is also highly import-dependent and is therefore subject to global disruption and volatility.

Speaking about the announcement, Owner of Sundown Pastoral Company David Statham said “Agriculture is always adapting – as farmers we have adapted for generations. We have been measuring our emissions and reductions for the past five years. There is an increasing demand for fibres that demonstrate a lower footprint and the GEGHA project allows us to further control the reduction of our emissions.”

By using GEGHA-produced ammonia, farmers can improve their environmental practices, plan sustainability for growing seasons and improve sustainability credentials to meet growing consumer demand for lower carbon products.

GEGHA demonstrates a pathway for meaningful decarbonisation of Australia’s agricultural sector by transforming the supply chain of perhaps its most vital input.

“The GEGHA project demonstrates how low-carbon ammonia can be integrated into regional farming through a scalable, cost-effective model. As both a template and a catalyst GEGHA paves the way for decentralised fertiliser production across NSW’s agricultural valleys – cutting emissions, meeting demand, and driving a more resilient regional economy,” Mr Clennett concludes.

Project financing had been provided by National Australia Bank (NAB). NAB Executive for Regional and Agribusiness Khan Horne said, “This pioneering project could help transform Australian agriculture by enabling a more resilient, low-emissions future. As the bank for one in three Aussie agribusinesses, we’re committed to backing customers tackling challenges like access to affordable, low-emissions fertiliser. We’re proud to support GEGHA’s vision and its ambition to help farmers cut emissions, and boost profitability.”

This project is proudly funded by the NSW Government in association with Hiringa Energy and Sundown Pastoral Company under the Net Zero Plan Stage 1: 2020-2030.

The facility expected to be fully operational in early 2027.

GEGHA at a glance

The GEGHA Project is being delivered as a joint venture between Sundown Pastoral Company and Hiringa Energy Limited, managed by Hiringa Energy Pty Ltd.

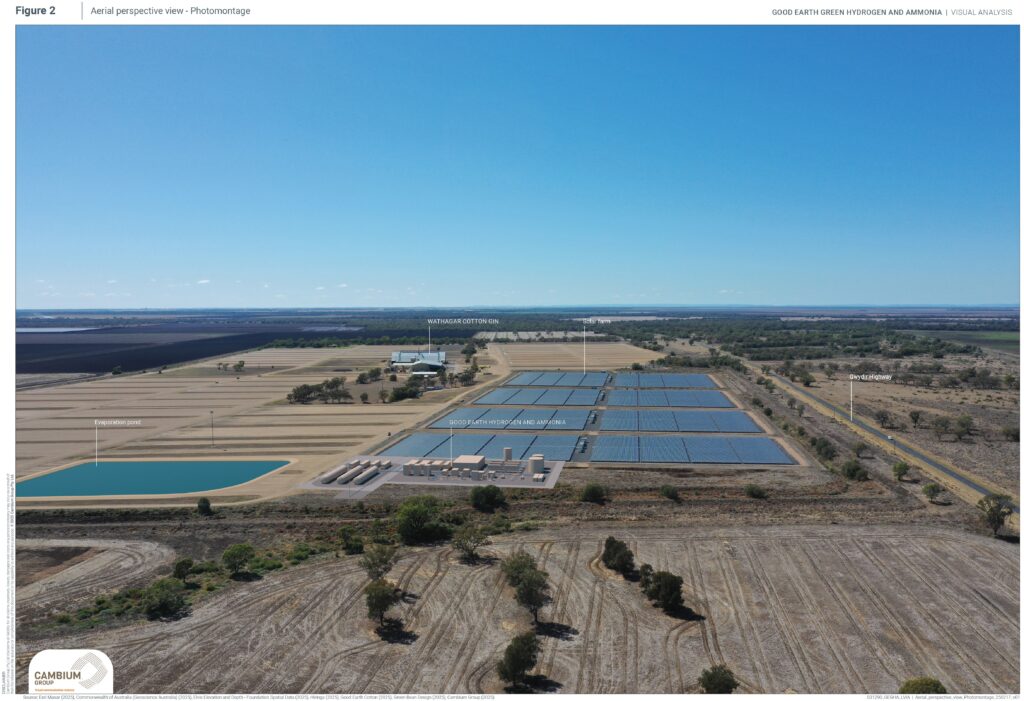

The project will be located on Sundown Pastoral Company land just off the Gwydir Highway, 33km south-west of Moree, NSW. The GEGHA plants will be constructed adjacent to an existing 9 MW solar farm and the Wathagar Cotton Gin.

The GEGHA project basis of design includes:

- 36MW of solar generation capacity including an existing 9 MW array and 27 MW of new capacity, supported by a 41 MWh battery energy storage system (BESS) and low-capacity grid connection.

- 15 MW of electrolysis, producing hydrogen from renewable electricity and locally sourced water supply.

- A 16 tonne per day ammonia plant, utilising hydrogen and air-captured nitrogen to manufacture ammonia.

- 600 tonnes of ammonia storage capacity to manage variable renewable energy supply and seasonal ammonia demand.

- 3 tonnes of hydrogen storage.

The GEGHA project concept is scalable and repeatable. Hiringa are currently progressing plans for expansion projects in both NSW’s Riverina and Gwydir regions. Each plant will include over 50 MW of electrolysis to produce ~20,000 tonnes of ammonia production annually, to serve demand more broadly across regional New South Wales & Queensland at low distribution cost.