Nano-thin ‘liquid-like’ coatings pave the way for a self-cleaning world

A biodegradable alternative to ‘forever chemicals’ with numerous applications.

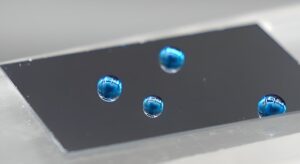

Droplets on a slippery surface [Credit: Isaac Gresham]

University of Sydney researchers have observed oil molecules retaining their ‘liquid-like’ properties when they are chemically attached as an extremely thin layer to solid surfaces, opening new possibilities for designing sustainable materials with non-stick characteristics.

The findings are published in the leading chemistry journal Angewandte Chemie, led by Dr Isaac Gresham with co-authors Professor Chiara Neto and honours student Seamus Lilley from the School of Chemistry and Sydney Nano, Dr Kaloian Koynov from the Max Planck Institute for Polymer Research and Dr Andrew Nelson from the Australian Centre for Neutron Scattering.

The ‘liquid-like’ coatings the team studied, known as slippery covalently-attached liquid surfaces (SCALS), are produced from silicones or polyethylene glycol – both of which break down into harmless byproducts in the environment.

SCALS are anti-adhesive without relying on problematic perfluorinated polymers (PFAS), known as ‘forever chemicals’ that are usually used for their low adhesion properties.

“These liquid-like layers are extremely slippery to most contaminants: they shed liquid droplets effortlessly, which is great to increase the efficiency of heat transfer and for collecting water, they prevent the buildup of scale, and resist the adhesion of ice and bacteria, bringing us one step closer to a self-cleaning world,” said Professor Neto, who leads the Nano-Interfaces Laboratory at the University of Sydney.

“We can correlate the exceptional performance of these layers with their nanostructure – meaning we now know what we’re aiming for when we design slippery surfaces, enabling us to make them even more effective and provide viable alternatives to fluorinated coatings.”

“A water droplet glides with no friction over a thick oil film, but if you completely remove the oil film, say by using soap, most water droplets will stick to solid surfaces,” Professor Neto said.

“How thin can the oil layer be on a solid surface before it is no longer ‘liquid-like’? At the nanoscale, the definition of a liquid becomes somewhat slippery.”

To unravel the secrets of their ultra-thin liquid coatings, the team used two techniques to ‘see’ the surface layers.

The first technique is single-molecule force spectroscopy, which measures the length of individual molecules and the force required to stretch or compress them.

The second is neutron reflectometry, which allows scientists to measure the length and grafting density of molecules.

“We found that if the liquid molecules were too short and sparsely grafted on the solid surface, they did not adequately cover the underlying solid surface and remained sticky,” Professor Neto said.

“On the other hand, if molecules were too long or grafted too densely, they did not have enough flexibility to act like a liquid.

“For SCALS to be effective, they needed to be in a Goldilocks zone, where they are neither too short nor too long, nor packed too loose or too tight.”

To show definitively that the exceptional properties of these layers are due to their ‘liquid-like’ state, the team measured the speed that a small probe molecule diffused inside the layer.

Molecules can diffuse through liquids, but not through solids. Professor Neto said the fastest molecular diffusion was observed in the Goldilocks zone, where the oil molecules are just the right length and grafted with moderate density.