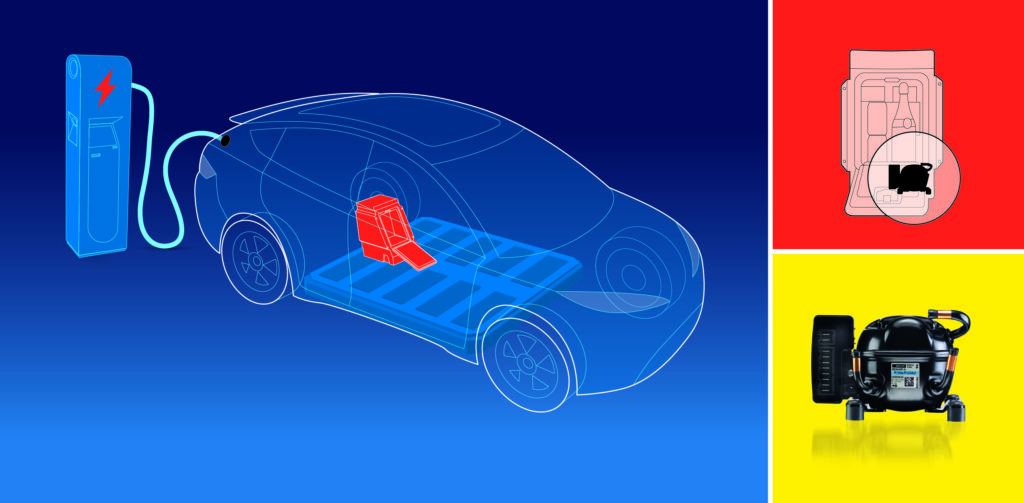

New compact and efficient compressor new trend for electric cars

Chilled Drinks and Food During Trips

There is an increasing demand and trend for onboard refrigerators in cars, and technology is making this a reality. In response to automotive customers’ constant search for greater comfort, onboard refrigerators will be available as a standard or optional feature in both top luxury brands and more mainstream models.

Electric vehicles in particular are already able to supply a cooling unit with power to keep drinks and food perfectly chilled.

The BD Nano compressor from Secop sets new standards in reliability and cooling performance of the fridge. Its predecessor, the BD Micro, is the current benchmark in the automotive market and is already used in premium car brand models equipped with a fridge. The BD Nano provides a solution that is smaller, quieter, and more powerful than the BD Micro.

Compact, Powerful, and Quiet

The compressor BDN45F-A from the BD Nano new series is optimised for R134a/R1234yf refrigerants and offers – in a compact size – premium cooling performance, high efficiency, and low noise and vibration.

The BD Nano’s footprint is 93 millimetres tall with a weight of just 1.5 kilograms, perfect for small cars’ fridges to maximise the room for food and drinks. Its efficiency (COP) can reach up to 1.53 W/W (ASHRAE LBP). The result combines low energy consumption, extended battery life, and an optimised total cost of ownership.

At 58.7W (ASHRAE LBP), the cooling capacity of the compact Nano continues to push the envelope. It means the temperature pull-down is fast to quickly cool the content of the fridge.

Thanks to improved acoustic comfort for noise-sensitive applications, Secop was able to reduce sound levels by 6 dB/A compared to the BD Micro, the predecessor of the BD Nano and current benchmark in the cars’ cooling solution market segment.

Another strength of the BD Nano is its reliability, since it features ISO16750 compliance for reduced knocking noise, vibration, and improved transport stability. With electromagnetic sensitive applications in mind, the Nano’s controller also features low interference (EMI CISPR25 Level 5) designed for controlled emissions and immunity against external sources.

The BD Nano is controlled by a new-generation Electronic Controller Unit (ECU), offering users a wide range of electronic interface functions. The ECU can be configured via an easy-to-deploy Modbus interface using industry-standard LIN hardware.

The control unit is designed as a universal, easy-to-use, and feature-rich compressor controller, with increased functionality provided via Secop’s free Tool4Cool software, an application that allows for even more customised programming.

Key features include:

- A wide-range input for DC power supply,

- Extended operating envelopes,

- Full battery protection,

- Integrated and configurable electronic thermostat functionality,

- Variable speed control of the compressor,

- Adjustable speed suppression to avoid cabinet resonances, and

- Easy-to-optimise parameters to ensure a sustainable cooling source.

Designed by the German compressor specialists at Secop, the BD Nano compressor can be used in more than just passenger cars; it’s also perfect in trucks, buses, recreational vehicles, and boats.

The Nano is manufactured at the Secop plant in Tianjin, China. This state-of-the-art facility has been IATF16949 certified since December 2023 and complies with the strict standards of the automotive industry.

This video demonstrates how the BD Nano compressor works, as well as its other uses including in the medical sector: https://vimeo.com/926934394/2a1a1a3608?share=copy