Rockwell Automation partner for OZ West Musgrave Project

Sustainably mining the in-demand minerals for Electric Vehicle (EV) and battery production

Rockwell Automation will be the automation partner for OZ Minerals’ West Musgrave copper-nickel project. The company will supply control systems including its PlantPAx distributed control system, and advanced control and information management systems.

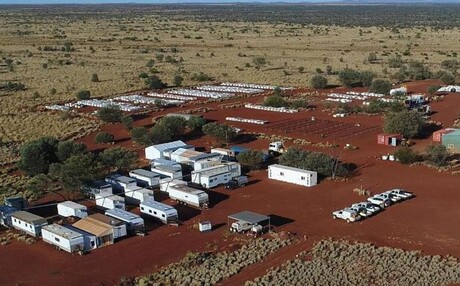

OZ Minerals specialises in extracting minerals important for a low carbon future. The West Musgrave Project is a greenfield copper and nickel project located in the remote Ngaanyatjarra Aboriginal Lands of central Western Australia near the intersection of the borders of Western Australia, South Australia, and the Northern Territory.

Production is expected to commence in the second half of 2025. Energy transition minerals like copper and nickel are in high demand globally as the world moves into the de-carbonisation and electrification era.

Once operational, West Musgrave is expected to be one of the world’s largest copper and nickel projects. It will also be one of the largest fully off-grid, hybrid renewable powered mines in the world. Initially 80% of its energy will be sourced from renewable wind and solar and there are plans to transition to an electric haulage fleet in the future.

Rockwell Automation’s Control Systems will be installed throughout the West Musgrave Minerals Processing Plant to provide an integrated solution for the control and monitoring of the processing plant’s equipment and processes. The systems will be used to control and monitor the mine’s ore processing plant.

“Modern minerals producers like OZ Minerals are looking to minimise their carbon footprints by using renewable energy, electrifying their fleets, and working with technology providers like Rockwell Automation to be more productive and more sustainable. We are honored to be working with them on this globally important project,” said Rockwell Automation’s regional director for the South Pacific region, Anthony Wong.

Rockwell Automation works with miners and manufacturers across the Electric Vehicle (EV) supply chain from mining right through to vehicle and battery production. Helping them to transform to meet the demands of a low carbon future.

The company recently published its 2022 Sustainability Report, a digital document that showcases how Rockwell is partnering across the manufacturing and mining industries and communities worldwide to create sustainable impact and change.