Sevaan Group to relocate to accommodate growth

Sevaan Group is relocating its manufacturing plant to Smeaton Grange in NSW. Sevaan Group is a dedicated, metal component and product manufacturing firm in Australia. Since 1997, it has grown from a small family business into a leading metal engineering, fabrication and finishing firm.

The relocation to Smeaton Grange is in response to the Group’s continued growth. According to David Green, CEO, Sevaan Group, the current premises which are located at Minto in NSW are no longer big enough to accommodate the Group’s immediate and projected growth.

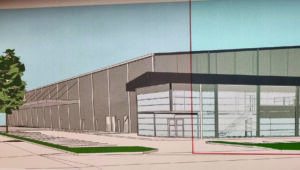

Drawing of the new Sevaan Group Facility.

“We actually require additional physical space to facilitate investment in new equipment to meet the growth we are currently experiencing, as well as that predicted in the future. Unfortunately, however, our two current sites do not have additional space to give. The move to Smeaton Grange will provide us with some 7500m2 just for production, which is a significant amount of space and almost double what we currently occupy,” explained David.

“We actually require additional physical space to facilitate investment in new equipment to meet the growth we are currently experiencing, as well as that predicted in the future. Unfortunately, however, our two current sites do not have additional space to give. The move to Smeaton Grange will provide us with some 7500m2 just for production, which is a significant amount of space and almost double what we currently occupy,” explained David.

The relocation will also allow the company to integrate its two current operations, the main manufacturing plant and the finishing plant, into one to give the company the platform it requires to deliver its ambitious five-year growth plan.

Sevaan Group will construct its new purpose-built facility during the remainder of 2023.

Apart from a production area, the plant will also feature a designated state-of-the-art concept and prototyping hub. The facility will also include offices, a seminar room, meeting rooms and a boardroom.

“We envisage the new plant will be a flagship facility for our contract manufacturing operation, which incorporates component and assembly manufacturing including sheet metal production, precision machining and finishing operations. We also believe it will provide an excellent working and learning environment for staff,” said David.

The Group expects to occupy the new premises in January 2024 and to be fully operational by February 2024.

“The investment in the Smeaton Grange facility and in new equipment will enhance both our capacity and capability to better meet the needs of our customers. It also represents the latest step in cementing our position as a truly leading and pioneering enterprise in end-to-end parts manufacturing,” said David.