Hugely durable Wearply outstanding for materials handling and electrical tasks

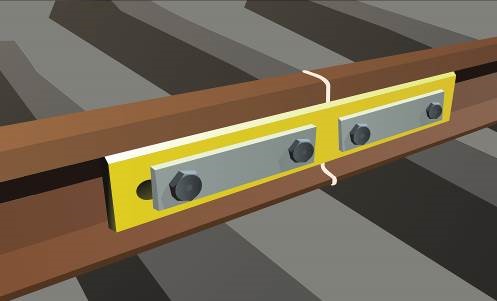

In the picture (below):Wearply from Cut To Size Plastics is used for applications ranging from insulated rail joints, above, through to vibratory conveyor leaf springs used in processing and loading equipment as well as electrical motor, generator and transformer components.

A hugely durable reinforced plastic composite that weighs less than aluminium but has up to 10 times the specific strength of 1020 steel is being offered by Cut To Size Plastics for demanding rail, ports, mineral processing, materials handling facilities, infrastructure construction and associated electrical and industrial applications.

Wearply reinforced plastic composite is ideal for maintenance, engineering and fabrication tasks which aim to optimise design and performance of infrastructure and machinery components and leaf spring assemblies in which performance and reliability is vital.

Wearply can withstand millions of stress cycles at 1400 bar (20,000 psi) without fatigue failure, says Pat Flood, NSW Manager of Cut To Size Plastics.

It derives its enormous strength, performance and durability from epoxy resins reinforced with continuously aligned, non-woven filaments. This allows plies to be laid so reinforcement is oriented to give greater strength and stiffness in the direction, or directions, in which it is most needed.

Parallel filaments resist the stress abrasion that can shorten the fatigue life in conventional reinforced plastics.

“This advanced engineering material is winning the attention of machinery designers globally for its superior performance in a huge range of applications, from rail, materials handling facilities and associated electrical plant through to vibratory machinery in minerals and primary production processing and loading applications.

“The same qualities that make it suitable for advanced aerospace and medical applications – such as helicopter blades and MRI equipment – mean it can be employed with confidence in rail, materials handling, marine and ship loading and high-precision tasks where reliability is vital,” says Mr Flood, who has national and international experience in the application of light but outstandingly durable engineering thermoplastics in applications including rail transport and infrastructure, materials handling, mining and electric machinery and plant.

Material advantages of Wearply include:

- High strength-to-weight performance, including 50 per cent greater compression strength than 1020 steel and a strength-to-weigh ratio up to 75x 106 mm. Aluminium is 45 per cent heavier

- Chemical and corrosion resistance – demonstrated in a wide range of vibratory conveyors, feeders and screening equipment working in aggressive environments, including rail and minerals loading facilities

- Improved electrical resistance – for performance as an electrical insulator in areas such as rail jointing, where it is used in standard, heavy duty and adhesive types, and as a structural high temperature composite in generators and transformers

- Damped vibration, noise and shock, qualities

- High impact strength and low notch sensitivity

- High resistance to fatigue, which, combined with other properties such as high dynamic strength, makes the material very suitable for helper, guide and drive springs in swing and screen technology

- Longer service life

- High temperature stability – dry service temperature up to 177 C (350F)

- High elastic storing capacity combined with high mechanical strength, to provide higher resiliency as compared with normal steel leaf springs, higher internal damping, well balanced resilience behaviours and six-fold storage capacity as to elastic energy compared with steel springs. Also used in shock and strut structures